The manufacturing industry is undergoing a digital transformation, with technological advancements and evolving consumer demands serving as major catalysts for change. The latest phase of this transformation, Industry 4.0, is revolutionizing the industry by integrating advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and Robotic Process Automation (RPA) into existing manufacturing processes. These technologies are helping manufacturers enhance their supply chain, logistics, and production lines, and evolve into smart factories.

At the same time, with remote and hybrid work arrangements becoming the norm, manufacturing businesses are also shifting to hybrid work models. Another recent survey from the National Association of Manufacturers (NAM), 46.8% of respondents pointed out that their company offers flexible arrangements to production workers, in addition to remote work. Manufacturing companies also tend to have a number of external parties as well such as suppliers, partners, outsourced staff. Managing the network and connectivity needs as well as ensuring the security of all these users poses a number of challenges for manufacturers.

Hybrid Work Challenges in the Manufacturing Sector

These technological developments and working models introduce new sets of challenges for manufacturers.

Security Concerns

Data security has always been a crucial consideration for manufacturing businesses, as they often deal with sensitive data, including proprietary designs, production processes, and intellectual property. According to the State of Smart Manufacturing Report from Rockwell Automation, cybersecurity risks were the biggest obstacle that manufacturers are looking to mitigate with smart manufacturing initiatives.

When there is also a need to enable access to this data for remote workers, it becomes critical to ensure that robust data security solutions are in place.

Increased Attack Surface as New Technologies Are Adopted

With the adoption of IoT devices and Industry 4.0 technologies, manufacturing systems are becoming more interconnected. This introduces more vulnerabilities from a security perspective as the attack surface for cyber threats expands. The result is an increase in attacks and financial losses as a consequence. The manufacturing sector saw 23.2% of the share of cyber attacks and a further 33% increase in the number of incidents caused by vulnerability exploitations from 2020 to 2021. The losses in the same period totalled up to £5,000 for 63% of manufacturers, with 22% losing between £5,000 and £25,000. In light of this increasing danger, it becomes crucial to secure the complex network of devices and systems in order to prevent data breaches and disruptions.

Demand for Scalable Architectures

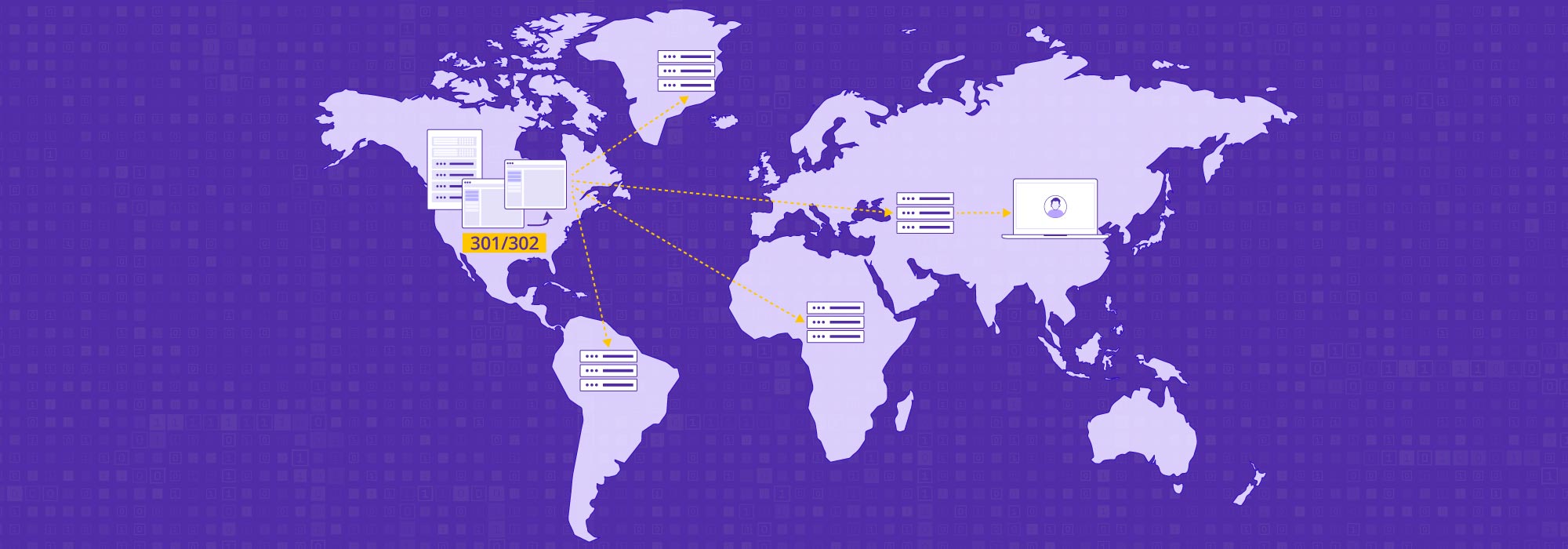

With the manufacturing sector experiencing a radical digital transformation, businesses need a networking architecture that can easily scale to keep up with increasing demands. There are more opportunities for global expansion now and this means setting up new sites in different geographical regions while ensuring that network connectivity remains optimum.

Traditionally, manufacturing businesses have adopted Multi-Protocol Label Switching (MPLS) for their connectivity needs. But this is not viable as the business grows since MPLS may not be supported in remote locations. SD-WAN (software-defined wide area network) is a potential workaround but still not sufficient for global needs.

Cloud Performance Needs Evolve

Part of the evolution seen in the manufacturing sector is the rapid adoption of cloud technologies. Various cloud applications such as Microsoft 365, Salesforce, SAP and FactoryTalk are being adopted in manufacturing to help improve employee productivity and performance, especially in hybrid arrangements. A survey on employees’ digital experience in the manufacturing industry revealed that 33% of IT leaders find the lack of appropriate SaaS or cloud services as one major obstacle. To serve these needs of better cloud performance too, advanced solutions are required, which can offer predictable and high-performance internet access.

Disconnect with Global Operations Hinders Efficiency

Manufacturing operations often require close coordination and collaboration among teams on the shop floor. In most cases, the organizational structure also involves global operations needing to be in close communication with their HQ, while production, engineering, suppliers and sales may be distributed across the world. This makes it an essential requirement to have robust connectivity that will meet the security and performance needs of all the dispersed teams and remote employees, for maintaining and improving overall operational efficiency.

Understanding Zero Trust and its Benefits

Zero Trust can help address a number of critical security and connectivity issues and even be a game-changer for the manufacturing industry. Traditionally, security operated under the assumption that once inside the network, users and devices could be trusted. However, in today’s sophisticated threat landscape, this approach proves inadequate. Zero Trust dismantles the old paradigm, adopting a “never trust, always verify” mindset.

In the manufacturing context, where sensitive data, intellectual property, and operational technology are at the core, Zero Trust becomes paramount. By requiring continuous authentication, authorization, and verification, Zero Trust minimizes the attack surface and ensures robust protection against cyber threats. But this Zero Trust approach should go hand in hand with effective Data Loss Prevention (DLP). DLP solutions help prevent unauthorized access, use, or transmission of sensitive data through a combination of content discovery, classification, policy enforcement, and monitoring. These DLP tools identify and classify sensitive data, establish policies specifying how data should be handled, and monitor network traffic, endpoints, and communication channels for potential violations.

CDNetworks’ Enterprise Secure Access Solution

To help manufacturers address the security and connectivity needs necessary today, CDNetworks offers Enterprise Secure Access, a cloud service that provides enterprises with secure remote access to applications and data.

ESA helps manufacturers take advantage of the Zero Trust approach to security, with a Software-Defined Perimeter(SDP) infrastructure to control access to and from any platform in any environment on any device. This Zero Trust implementation ensures that users’ identities, devices and behavior are checked and only authorized users and devices are granted access to enterprise applications. You should also add to this robust DLP solutions to identify and mitigate potential data breaches. The combination of Zero Trust and DLP allows manufacturers to mount a multi-layered defense strategy that can adequately meet the growing security demands.

With ESA, manufacturers can allow their geographically dispersed teams and remote employees access to data that they need, as this is taken care of by CDNetworks’ globally distributed DDoS-resistant edge network. This also allows the workers to access their SaaS applications and other enterprise resources seamlessly regardless of where they are located.